De Novo

Serving the Aerospace, Defense, Medical, and Automotive industries with rapid hardware development and delivery of high-quality parts and tools.

Capabilities

De Novo Specializes in the Following Capabilities

Tooling/Fixture Design

•. Composite Lay-up Tooling

•. Precision Alignment Jigging

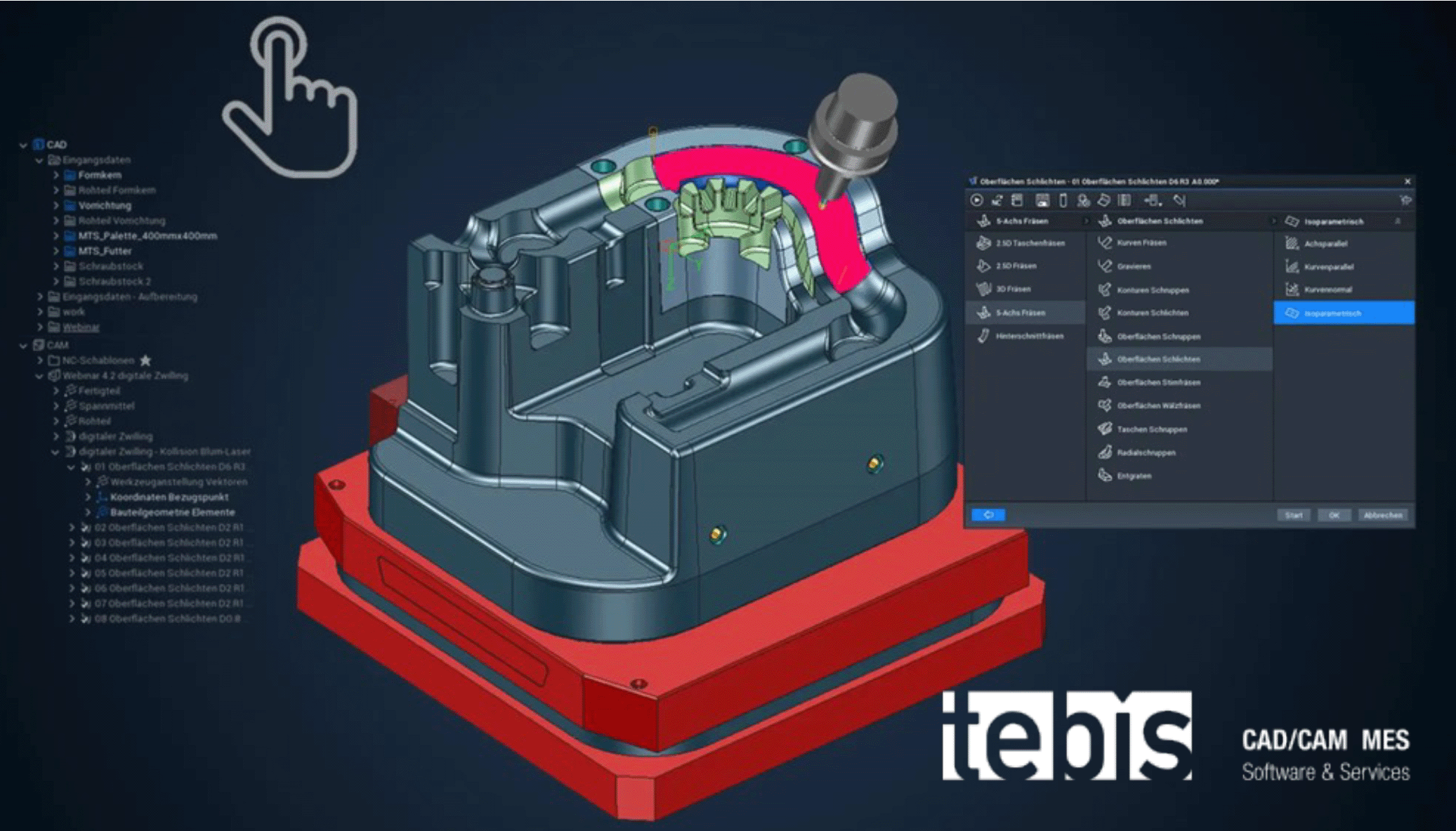

•. Full CAD and CAM expertise

5-axis Machining

•. Metal, Tooling Board, Composite

Close Contour Casting

• Exclusively partnered with RAMPF to offer a novel near-net Polyurethane casting system

•. Low cost - minimal amounts of machining

•. High performance – monolithic/bond free

•. Ideal material selection for large scale metal forms, composite tooling, vacuum fixtures

Fabrication

• Aluminum/Steel

• Machining Fixtures

• Ground Support equipment

• Jigs

• Check fixtures

• Handling Fixtures

• Carts

Key Equipment

Jobs LinX Compact 35

OVENS

About De Novo

De Novo was founded in March of 2021 with the mission to provide customers high quality parts with the best-in-class lead times. Our main priority is to always deliver excellence in service and workmanship.

De Novo is staffed by an elite team with over 20 years experience delivering hardware for the Aerospace, Defense, Medical, and Automotive industries. Whether it be 5 Axis Machining, Design (Tooling and Fixtures), Fabrication, or Assembly, De Novo strives to outperform our competition and build strong business relationships built on integrity. We look forward to working with you and your team.